Electronics#ar #VR #AR Glasses #Augmented Reality #Virtual Reality #techtok #cftech

Use this section to provide a description of your blog./pages/blog

Our AI glasses demo is called Redaly, one of early products from 2025

Posted by Technology Co., Ltd Shenzhen Mshilor

Read more

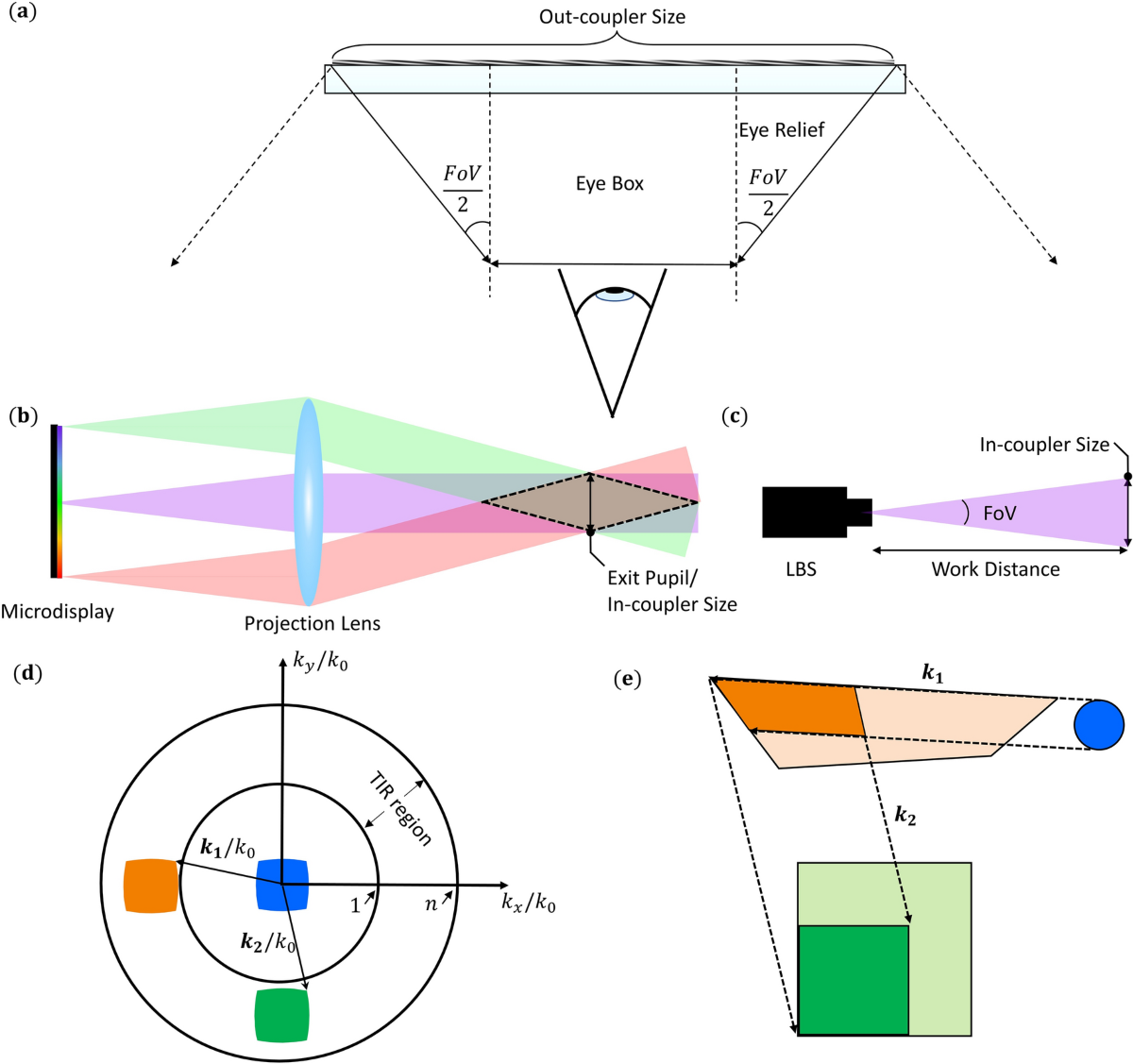

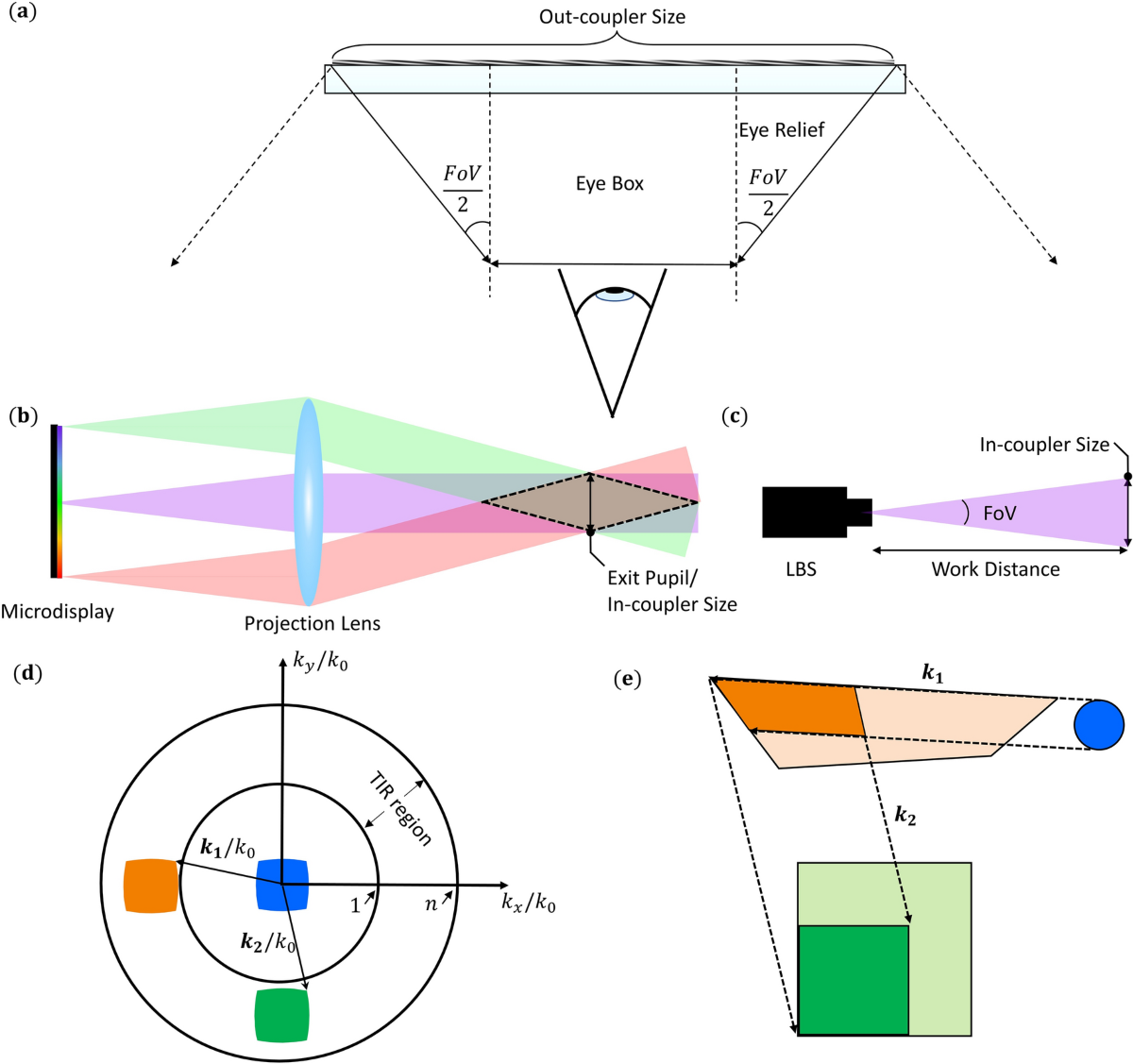

What are the most promising approaches to improving waveguide resolution?

Posted by Technology Co., Ltd Shenzhen Mshilor

Improving the resolution of waveguide displays is crucial for enhancing the visual experience in augmented reality applications. Here are some promising approaches to achieve better resolution:

1. Advanced Fabrication Techniques

- Nanoimprint Lithography: This technique allows for the creation of fine features at the nanoscale, enabling higher-resolution waveguides by improving light coupling and propagation.

- Laser Direct Write: Utilizing laser technology to create precise patterns on waveguide materials can enhance resolution while allowing for complex designs.

2. Micro-optical Elements

- Micro-lenses and Diffractive Optical Elements (DOEs): Incorporating micro-lenses or DOEs can improve light management within the waveguide, enhancing image clarity and resolution.

- Binary Optics: Using binary optics can help in shaping the light path more effectively, leading to improved focus and resolution.

3. Optimized Material Selection

- High Refractive Index Materials: Utilizing materials with higher refractive indices can improve light confinement and reduce losses, contributing to better resolution and image quality.

- Low-Scattering Materials: Selecting materials with minimal scattering properties can help maintain clarity and detail across the display.

4. Multi-layer Waveguide Designs

- Layered Structures: Developing multi-layer waveguide designs can allow for more complex light processing, improving the effective resolution by using different layers for different optical functions.

- Gradient Index Waveguides: Employing gradient index profiles can help in better light manipulation and focusing, enhancing overall resolution.

5. Improved Light Sources

- High-Resolution Micro-displays: Using higher-resolution micro-displays as light sources can directly boost the effective resolution of the waveguide by providing finer pixel details.

- Laser-based Light Sources: Employing laser sources can result in sharper images due to their coherence and directionality, improving overall display quality.

6. Adaptive Optics

- Real-time Adjustments: Integrating adaptive optics technologies can allow for real-time adjustments to the light path, optimizing resolution based on the viewing conditions and user needs.

- Feedback Mechanisms: Using sensors to monitor image quality and adjust optical elements dynamically can help maintain high resolution.

7. Digital Signal Processing

- Image Enhancement Algorithms: Implementing advanced image processing techniques can improve perceived resolution by sharpening images and reducing artifacts.

- Super-resolution Techniques: Utilizing algorithms that combine multiple images to create a higher-resolution output can enhance the overall visual experience.

Conclusion

These approaches represent a combination of material science, optical engineering, and digital processing advancements that can collectively enhance the resolution of waveguide displays. Continuous research and innovation in these areas are essential for overcoming current limitations and improving the user experience in augmented reality applications.

Read more

Improving the resolution of waveguide displays is crucial for enhancing the visual experience in augmented reality applications. Here are some promising approaches to achieve better resolution:

1. Advanced Fabrication Techniques

- Nanoimprint Lithography: This technique allows for the creation of fine features at the nanoscale, enabling higher-resolution waveguides by improving light coupling and propagation.

- Laser Direct Write: Utilizing laser technology to create precise patterns on waveguide materials can enhance resolution while allowing for complex designs.

2. Micro-optical Elements

- Micro-lenses and Diffractive Optical Elements (DOEs): Incorporating micro-lenses or DOEs can improve light management within the waveguide, enhancing image clarity and resolution.

- Binary Optics: Using binary optics can help in shaping the light path more effectively, leading to improved focus and resolution.

3. Optimized Material Selection

- High Refractive Index Materials: Utilizing materials with higher refractive indices can improve light confinement and reduce losses, contributing to better resolution and image quality.

- Low-Scattering Materials: Selecting materials with minimal scattering properties can help maintain clarity and detail across the display.

4. Multi-layer Waveguide Designs

- Layered Structures: Developing multi-layer waveguide designs can allow for more complex light processing, improving the effective resolution by using different layers for different optical functions.

- Gradient Index Waveguides: Employing gradient index profiles can help in better light manipulation and focusing, enhancing overall resolution.

5. Improved Light Sources

- High-Resolution Micro-displays: Using higher-resolution micro-displays as light sources can directly boost the effective resolution of the waveguide by providing finer pixel details.

- Laser-based Light Sources: Employing laser sources can result in sharper images due to their coherence and directionality, improving overall display quality.

6. Adaptive Optics

- Real-time Adjustments: Integrating adaptive optics technologies can allow for real-time adjustments to the light path, optimizing resolution based on the viewing conditions and user needs.

- Feedback Mechanisms: Using sensors to monitor image quality and adjust optical elements dynamically can help maintain high resolution.

7. Digital Signal Processing

- Image Enhancement Algorithms: Implementing advanced image processing techniques can improve perceived resolution by sharpening images and reducing artifacts.

- Super-resolution Techniques: Utilizing algorithms that combine multiple images to create a higher-resolution output can enhance the overall visual experience.

Conclusion

These approaches represent a combination of material science, optical engineering, and digital processing advancements that can collectively enhance the resolution of waveguide displays. Continuous research and innovation in these areas are essential for overcoming current limitations and improving the user experience in augmented reality applications.

Read more

What are the limitations of each coupling technique?

Posted by Technology Co., Ltd Shenzhen Mshilor

Each advanced optical coupling technique has its own set of limitations. Here’s a breakdown of the limitations associated with each method:

1. Grating Couplers

-

Limitations:

- Wavelength Sensitivity: Performance can vary with different wavelengths of light, making them less effective for multi-wavelength systems.

- Design Complexity: Designing gratings to achieve specific coupling angles can be complex and may require precise fabrication techniques.

- Efficiency Loss: Some light may be lost due to scattering, especially if the gratings are not optimally designed.

2. Evanescent Wave Coupling

-

Limitations:

- Distance Sensitivity: The efficiency of evanescent coupling drops significantly with distance, requiring precise alignment of the waveguide and the light source.

- Limited Range: This technique is more suited for short-distance coupling, which may not be ideal for all applications.

- Complex Integration: Integrating this method into existing systems can be challenging due to alignment issues.

3. Lenticular Arrays

-

Limitations:

- Optical Distortion: Poorly designed lenticular arrays can introduce optical distortions, affecting image quality.

- Limited FOV: While they can enhance FOV, their effectiveness may diminish as the viewing angle increases, leading to potential image artifacts.

- Increased Complexity: The design and manufacturing processes can become more complex and costly than simpler coupling methods.

4. Optical Tapers

-

Limitations:

- Manufacturing Challenges: Creating optical tapers with precise dimensions can be difficult, potentially increasing production costs.

- Losses at Interfaces: If not designed correctly, there can still be significant losses at the interface between the taper and the waveguide.

- Size Constraints: The size and shape of the taper may limit the overall design flexibility of the system.

5. Micro-Mirror Arrays

-

Limitations:

- Alignment Sensitivity: Requires precise alignment to ensure that light is directed correctly, which can complicate assembly.

- Mechanical Reliability: Moving parts can introduce reliability issues, as wear and tear may affect performance over time.

- Cost: The complexity of manufacturing micro-mirror arrays can lead to higher production costs.

6. Reflective and Refractive Elements

-

Limitations:

- Surface Quality Dependency: The performance can be highly dependent on the quality of the optical surfaces, which can be difficult to maintain.

- Potential Losses: Reflective elements can introduce losses due to absorption and scattering, particularly if not coated properly.

- Design Complexity: Achieving the desired optical performance may require complex designs and precise fabrication techniques.

7. Adaptive Optics

-

Limitations:

- Cost and Complexity: The technology can be expensive and complex to implement, requiring sophisticated control systems.

- Response Time: Adaptive systems may have limitations in response time, which could affect real-time applications.

- Power Consumption: These systems can consume more power than fixed optics, impacting battery life in portable devices.

8. Surface Texturing

-

Limitations:

- Manufacturing Consistency: Achieving uniform texture across large surfaces can be challenging, leading to variability in performance.

- Potential for Scattering: Incorrectly designed textures may result in unwanted scattering and degrading image quality.

- Limited Effective Range: Surface textures may be effective only within a specific range of angles or wavelengths.

Conclusion

Understanding these limitations is crucial for selecting the appropriate optical coupling technique for waveguide displays. Advances in materials science and fabrication technologies may mitigate some of these challenges, leading to improved performance and broader applications in augmented reality.

Read more

Each advanced optical coupling technique has its own set of limitations. Here’s a breakdown of the limitations associated with each method:

1. Grating Couplers

-

Limitations:

- Wavelength Sensitivity: Performance can vary with different wavelengths of light, making them less effective for multi-wavelength systems.

- Design Complexity: Designing gratings to achieve specific coupling angles can be complex and may require precise fabrication techniques.

- Efficiency Loss: Some light may be lost due to scattering, especially if the gratings are not optimally designed.

2. Evanescent Wave Coupling

-

Limitations:

- Distance Sensitivity: The efficiency of evanescent coupling drops significantly with distance, requiring precise alignment of the waveguide and the light source.

- Limited Range: This technique is more suited for short-distance coupling, which may not be ideal for all applications.

- Complex Integration: Integrating this method into existing systems can be challenging due to alignment issues.

3. Lenticular Arrays

-

Limitations:

- Optical Distortion: Poorly designed lenticular arrays can introduce optical distortions, affecting image quality.

- Limited FOV: While they can enhance FOV, their effectiveness may diminish as the viewing angle increases, leading to potential image artifacts.

- Increased Complexity: The design and manufacturing processes can become more complex and costly than simpler coupling methods.

4. Optical Tapers

-

Limitations:

- Manufacturing Challenges: Creating optical tapers with precise dimensions can be difficult, potentially increasing production costs.

- Losses at Interfaces: If not designed correctly, there can still be significant losses at the interface between the taper and the waveguide.

- Size Constraints: The size and shape of the taper may limit the overall design flexibility of the system.

5. Micro-Mirror Arrays

-

Limitations:

- Alignment Sensitivity: Requires precise alignment to ensure that light is directed correctly, which can complicate assembly.

- Mechanical Reliability: Moving parts can introduce reliability issues, as wear and tear may affect performance over time.

- Cost: The complexity of manufacturing micro-mirror arrays can lead to higher production costs.

6. Reflective and Refractive Elements

-

Limitations:

- Surface Quality Dependency: The performance can be highly dependent on the quality of the optical surfaces, which can be difficult to maintain.

- Potential Losses: Reflective elements can introduce losses due to absorption and scattering, particularly if not coated properly.

- Design Complexity: Achieving the desired optical performance may require complex designs and precise fabrication techniques.

7. Adaptive Optics

-

Limitations:

- Cost and Complexity: The technology can be expensive and complex to implement, requiring sophisticated control systems.

- Response Time: Adaptive systems may have limitations in response time, which could affect real-time applications.

- Power Consumption: These systems can consume more power than fixed optics, impacting battery life in portable devices.

8. Surface Texturing

-

Limitations:

- Manufacturing Consistency: Achieving uniform texture across large surfaces can be challenging, leading to variability in performance.

- Potential for Scattering: Incorrectly designed textures may result in unwanted scattering and degrading image quality.

- Limited Effective Range: Surface textures may be effective only within a specific range of angles or wavelengths.

Conclusion

Understanding these limitations is crucial for selecting the appropriate optical coupling technique for waveguide displays. Advances in materials science and fabrication technologies may mitigate some of these challenges, leading to improved performance and broader applications in augmented reality.

Read more

What specific health metrics will AI glasses track in 2025?

Posted by Technology Co., Ltd Shenzhen Mshilor

In 2025, AI glasses are expected to track a variety of specific health metrics, leveraging advanced sensors and AI algorithms. Here are some anticipated metrics:

1. Heart Rate

- Continuous monitoring of heart rate to help users understand their cardiovascular health and fitness levels.

2. Activity Levels

- Tracking steps, distance traveled, and overall physical activity to promote a more active lifestyle.

3. Caloric Expenditure

- Estimating calories burned throughout the day based on activity levels and heart rate data.

4. Sleep Quality

- Monitoring sleep patterns and quality, including duration and cycles, to provide insights into rest and recovery.

5. Stress Levels

- Assessing stress indicators through heart rate variability and other physiological signals to help users manage their mental well-being.

6. Oxygen Saturation

- Measuring blood oxygen levels to monitor respiratory health, especially useful for individuals with certain medical conditions.

7. Body Temperature

- Tracking body temperature to detect potential fevers or changes in health status.

8. Posture and Movement Analysis

- Providing feedback on posture and movement to help prevent musculoskeletal issues and promote ergonomic practices.

9. Hydration Levels

- Monitoring hydration status through sweat analysis to encourage proper fluid intake.

10. Mood and Emotional State

- Utilizing facial recognition and biometric data to assess mood changes, providing insights into mental health.

Conclusion

The integration of these health metrics in AI glasses will enable users to monitor their well-being more effectively and make informed lifestyle choices, contributing to overall health and fitness management.

Read more

In 2025, AI glasses are expected to track a variety of specific health metrics, leveraging advanced sensors and AI algorithms. Here are some anticipated metrics:

1. Heart Rate

- Continuous monitoring of heart rate to help users understand their cardiovascular health and fitness levels.

2. Activity Levels

- Tracking steps, distance traveled, and overall physical activity to promote a more active lifestyle.

3. Caloric Expenditure

- Estimating calories burned throughout the day based on activity levels and heart rate data.

4. Sleep Quality

- Monitoring sleep patterns and quality, including duration and cycles, to provide insights into rest and recovery.

5. Stress Levels

- Assessing stress indicators through heart rate variability and other physiological signals to help users manage their mental well-being.

6. Oxygen Saturation

- Measuring blood oxygen levels to monitor respiratory health, especially useful for individuals with certain medical conditions.

7. Body Temperature

- Tracking body temperature to detect potential fevers or changes in health status.

8. Posture and Movement Analysis

- Providing feedback on posture and movement to help prevent musculoskeletal issues and promote ergonomic practices.

9. Hydration Levels

- Monitoring hydration status through sweat analysis to encourage proper fluid intake.

10. Mood and Emotional State

- Utilizing facial recognition and biometric data to assess mood changes, providing insights into mental health.

Conclusion

The integration of these health metrics in AI glasses will enable users to monitor their well-being more effectively and make informed lifestyle choices, contributing to overall health and fitness management.

Read more

What specific military technologies are integrated into IVAS?

Posted by Technology Co., Ltd Shenzhen Mshilor

The Integrated Visual Augmentation System (IVAS) goggles incorporate several advanced military technologies designed to enhance situational awareness and operational effectiveness for soldiers. Here are some key technologies integrated into the IVAS:

1. Augmented Reality (AR)

- Information Overlay: The goggles provide real-time overlays of vital information, including maps, mission data, and threat assessments, directly in the soldier's field of view.

2. Night Vision

- Low-Light Operation: IVAS integrates advanced night vision technology, allowing soldiers to operate effectively in low-light conditions without the need for separate night vision goggles.

3. Thermal Imaging

- Heat Signature Detection: The goggles can detect and display thermal signatures, which is crucial for identifying threats and targets in various environmental conditions.

4. Advanced Sensors

- Environmental Awareness: Integrated sensors monitor environmental factors (e.g., atmospheric conditions) to provide context-aware information.

5. Communication Systems

- Secure Data Transmission: The IVAS supports secure communication channels, enabling soldiers to share information and coordinate operations effectively in real-time.

6. GPS and Navigation

- Positioning and Navigation: The system includes GPS capabilities to provide precise positioning and navigation, allowing soldiers to navigate unfamiliar terrain confidently.

7. Head-Mounted Display (HMD)

- High-Resolution Display: The goggles feature a high-resolution head-mounted display that ensures clear visibility of overlaid information and graphics.

8. Gesture and Voice Control

- Hands-Free Operation: The IVAS supports gesture recognition and voice commands, allowing soldiers to interact with the system without needing to use their hands, which is critical in combat situations.

9. Data Integration

- Interoperability with Other Systems: The system can integrate with various military databases and other digital systems, allowing for a comprehensive operational picture.

10. Durability and Ruggedness

- Field-Ready Design: IVAS is designed to withstand harsh environmental conditions, making it suitable for combat and field use.

Conclusion

These integrated technologies make IVAS a powerful tool for enhancing the effectiveness and safety of soldiers on the battlefield, providing them with critical information and capabilities in real-time. The focus on AR, advanced imaging, and secure communication reflects the evolving needs of modern military operations.

Read more

The Integrated Visual Augmentation System (IVAS) goggles incorporate several advanced military technologies designed to enhance situational awareness and operational effectiveness for soldiers. Here are some key technologies integrated into the IVAS:

1. Augmented Reality (AR)

- Information Overlay: The goggles provide real-time overlays of vital information, including maps, mission data, and threat assessments, directly in the soldier's field of view.

2. Night Vision

- Low-Light Operation: IVAS integrates advanced night vision technology, allowing soldiers to operate effectively in low-light conditions without the need for separate night vision goggles.

3. Thermal Imaging

- Heat Signature Detection: The goggles can detect and display thermal signatures, which is crucial for identifying threats and targets in various environmental conditions.

4. Advanced Sensors

- Environmental Awareness: Integrated sensors monitor environmental factors (e.g., atmospheric conditions) to provide context-aware information.

5. Communication Systems

- Secure Data Transmission: The IVAS supports secure communication channels, enabling soldiers to share information and coordinate operations effectively in real-time.

6. GPS and Navigation

- Positioning and Navigation: The system includes GPS capabilities to provide precise positioning and navigation, allowing soldiers to navigate unfamiliar terrain confidently.

7. Head-Mounted Display (HMD)

- High-Resolution Display: The goggles feature a high-resolution head-mounted display that ensures clear visibility of overlaid information and graphics.

8. Gesture and Voice Control

- Hands-Free Operation: The IVAS supports gesture recognition and voice commands, allowing soldiers to interact with the system without needing to use their hands, which is critical in combat situations.

9. Data Integration

- Interoperability with Other Systems: The system can integrate with various military databases and other digital systems, allowing for a comprehensive operational picture.

10. Durability and Ruggedness

- Field-Ready Design: IVAS is designed to withstand harsh environmental conditions, making it suitable for combat and field use.

Conclusion

These integrated technologies make IVAS a powerful tool for enhancing the effectiveness and safety of soldiers on the battlefield, providing them with critical information and capabilities in real-time. The focus on AR, advanced imaging, and secure communication reflects the evolving needs of modern military operations.

Our AI glasses demo is almost done; We will assemble and test this afternoon. The strength of teamwork is powerful. Let us join hands to create prosperity.